Case Study:

Daily Thousands of bottles travel with production. In PIR, after production, bottles send to growth rooms where client arrange them by their products & verities. Bottles stay for some weeks in growth room where bottles keep under observation. Wastage bottles scan by WIFI BARCODE reader and data feed into LIMS.

From growth rooms, bottles may send to 1. IPQC (for examination), 2. Green House (Plants are ready for farmers) or 3. Other Locations (as samples).

After few weeks, bottles shift to IPQC, where experts examine them. Experts give them culture type as per their growth. Again bottles send to PIR from IPQC for reprocess. This cycle repeats until they get satisfactory result.

Proposed Solutions:

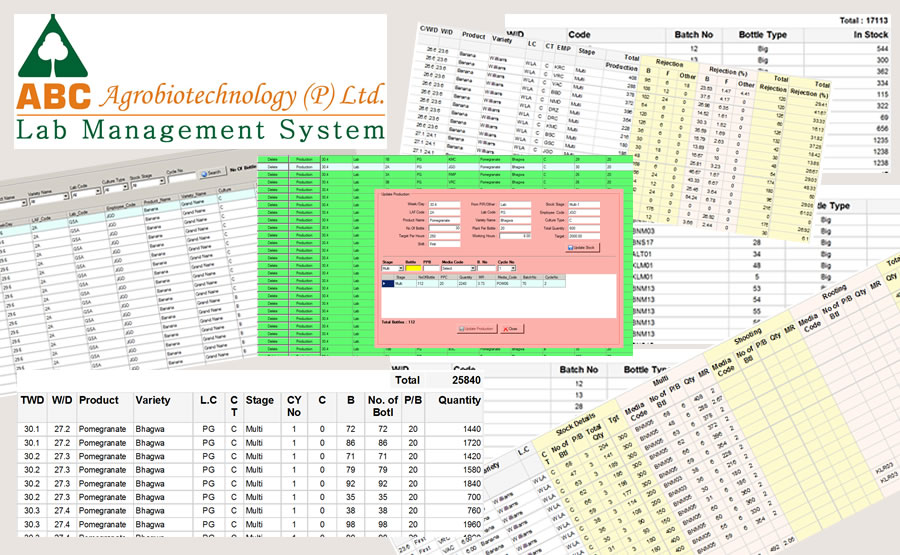

With vast case study of Bio-agriculture complex planting system, peculiar have developed “Lab Inventory Management System (LIMS)”, which empower management to control & manage plant production cycle.

LIMS provides two kind of easy input methods: 1. By entry forms and 2. By excel import, which consume fewer efforts to take whole day production data. We also integrated WIFI BARCODE reader to takes input direct from bottle label.

Several reports make easy decision making in raw material consumption, Stock limits, plants delivery timings, wastage management & more…

Modules:

Reports: